11.13 Midvale Slag NPL Site, Midvale UT

Contact: Scott Everett

Organization: Utah DEQ

Email: [email protected]

11.13.1 Site Description and Conceptual Site Model

The Midvale Slag National Priorities List (NPL) site is in Midvale City, Utah, approximately 12 miles south of Salt Lake City. The site is the location of former smelters that operated from the early 1900s until 1958. The site is 446 acres in size and is divided into two operable units (OU): OU1 is the northern 266 acres of the site; and OU2 occupies the southern 180 acres. This case study addresses only OU2. Ore processing and smelting operations were conducted at the site and the adjacent Sharon Steel Superfund Site, located immediately south of OU2. USEPA listed the Midvale Slag Superfund Site on the National Priorities List (NPL) in 1991 based on studies conducted between 1982 and 1985 that found groundwater, soil and sediments contaminated with heavy metals. Potential human health threats included drinking contaminated groundwater or ingesting, inhaling or handling contaminated soils, wastes, or sediments.

11.13.1.1 Lead on the site

Site investigations for OU2 focused on mixed smelter waste, slag, and groundwater. Surface and subsurface soil samples were analyzed in five mixed smelter waste areas, calcine waste, silver refinery waste, and contaminated soils. Historical waste disposal practices resulted in extensive slag deposits, which covered approximately 60% of the site. Most of the slag volume was attributable to six slag piles located in the northern and western portions of OU2. Slag from the site was known to contain elevated levels of arsenic and lead. Data on the concentrations of lead in each of the on-site slag piles are limited, but most values were between 4,000 ppm and 9,000 ppm.

11.13.1.2 Soil Type

The soil type at OU2 is a mixture of soil and mostly slag. Slag was spread across the entire site and distinct piles were formed because of smelting practices. Slag samples from six slag piles (Piles A through F) at OU2 were collected in June and July of 1993 and were sent to the University of Colorado for geochemical analysis and bioaccessibility. The speciated samples were not identical to the samples that were used to measure bioaccessibility and leachability, so conclusions on the correlation between speciation results and bioaccessibility/leachability results were drawn with caution (ISSI 1998).

Lead occurred in a wide variety of different mineral phases at the site, with substantial variation between samples, both within and between piles. On a frequency basis, slag particles were usually the most common, although one sample was composed mainly of lead sulfide particles and another sample was composed mainly of lead-aluminum particles. The concentration of lead in slag particles was usually low, and most of the lead tended to occur in small grains of lead-enriched material. Most of the samples contained 40-80% of the total lead in a liberated form. The predominant forms of lead in liberated grains included lead arsenic oxide or other lead metal oxides, along with lead carbonate and lead sulfates. Both total and liberated grains spanned a range of sizes, but most of the liberated grains tended to fall in the 20 to100 µm range.

11.13.1.3 Source of Lead

While the facility operated, five different lead and copper smelters occupied the site. The milled ores were smelted at the site to produce lead, arsenic, copper, and other metals. Contamination at the site is associated with smelter and mill waste deposits on OU2 as well as small amounts of surface and subsurface slag and contaminated soils on OU1. In addition to lead, contaminants of concern at the site include arsenic, barium, cadmium, chromium, copper, mercury, silver, and zinc.

Based on historical research of the former smelting facility, the material in each of the on-site slag piles differs based on process of origin. Piles A and B were designated as air-cooled slag piles and were probably reworked after being deposited. Air-cooled slag is gray to dark gray and is occasionally glassy. Pile C consisted of reject material placed by the former slag recovery operation, and may have contained slag from all areas of the site. Pile D was designated as the water-quenched pile based on its fine grain size and dark black color and glassy luster. Pile E was designated as the Iron Slag Area because of the iron oxide staining on the material. Pile F was designated as the Copper Slag Area and likely contained slag from a copper smelter that once occupied the area.

11.13.1.4 Land Use/ Exposure Scenarios

The land use scenario from the risk assessment (juvenile pig bioavailability study) evaluated a standard residential and commercial/industrial scenario. The land use scenario in the bioaccessibility study evaluated an expanded commercial scenario for the development of OU2. Three types of exposed populations were considered:

- Noncontact intensive (NCI) worker – an individual who works mainly indoors (such as a store clerk or an office worker). Exposure was assumed to occur both to indoor dust (in the workplace) and to outdoor soil/slag.

- Contact-intensive (CI) worker – an individual who works mainly outdoors and has frequent and extensive opportunity for contact with slag and slag-contaminated soils. Exposure to indoor dust is assumed to be minimal. Extensive exposure to outdoor soil/slag does not require that the individual be engaged in activities such as digging or earth-moving, but only that the individual is handling equipment or materials that are stored outdoor where contamination with dust from soil or slag is likely.

- Construction worker – an individual who does not work at the site full time, but may come on site for work (such as to install a utility line or construct a building).

11.13.2 Methodology Used for Evaluating Bioavailability

11.13.2.1 In Vivo Analysis

A sample of slag was collected from Pile D and tested by Region VIII using the in vivo swine model (Casteel et al. 1998; USEPA 1997). Young swine were selected for use in the study primarily because the gastrointestinal physiology and overall size of young swine are similar to that of young children, who are the population of prime concern for exposure to lead. The test material was collected from the northern portion of OU2 at the site from Pile D. The sample contained 7,900 ppm lead. The amount of lead present in blood or tissues of animals exposed to the test material was compared to that for animals exposed to lead acetate, and the results were expressed as relative bioavailability (RBA). The observed RBA for lead was 17%. This value was considered appropriate for Pile D, but it was not clear whether the same value should be applied to all slags on site. A series of tests were conducted to further characterize the physical nature of the various slags found on the site. The geochemical characteristics of the pile materials were compared, including parameters such as frequency and relative mass of each mineral phase, particle size distribution, and matrix association of particles. Speciation data demonstrated that there were physico-chemical differences between piles.

11.13.2.2 In Vitro Analysis

In vitro study test materials included a composite sample from each of the six slag piles (A through F) as well as a slag sample from Pile D that was originally used in the swine bioavailability assay. The laboratory first dried all samples and then sieved them to less than 250 µm particle size. The extraction fluid consisted of ASTM Type II deionized water, 0.4 M glycine and enough 12.1 N hydrochloric acid to bring the fluid to a pH of 1.5. One gram of test material was added to 100 mL of extraction fluid in a 126-mL extraction bottle which was then turned end-over-end at 30 ± rpm in a constant temperature (37°C) water bath for 1 hour. After an hour, the extraction procedure was terminated and the extract was filtered and analyzed via ICP for arsenic and lead concentrations. To determine the percent of lead that is absorbed into the stomach, an aliquot of the dried, sieved and composited test material was analyzed using ICP to determine total lead concentrations present prior to extraction.

The in vitro bioaccessibility results indicated that the bioaccessibility of lead in Pile D may be lower than for any of the other piles. At the time of this study, USEPA was undergoing validation and peer review of in vitro methods for estimating bioavailability; at the time, in vitro methods for estimating lead absorption showed promising results but were not completely validated. The data suggested that the RBA values for lead measured in the swine study are probably not directly applicable to Piles A, B, C, E, and F and that use of these RBA values without any sort of adjustment would probably tend to underestimate exposure and risk from lead in these piles. Results are shown in the following Table 11-13.

Table 11‑13. Relative bioaccessibility of lead in Midvale slag pile

| Slag Pile Test Material | Relative Bioaccessibility for Lead (%) | |

|---|---|---|

| Raw Value | Mean | |

| A-1 | 73 | 73 |

| A-2 | 73 | |

| B-1 | 78 | 78 |

| B-2 | 78 | |

| C-1 | 43 | 42 |

| C-2 | 42 | |

| D-1 | 12 | 12 |

| D-2 | 13 | |

| E-1 | 68 | 66 |

| E-2 | 65 | |

| F-1 | 45 | 47 |

| F-2 | 48 | |

| Swine fed-1 (Pile D) | 11 | 11 |

| Swine fed-2 (Pile D) | 11 | |

As shown in Table 11-13, duplicate samples displayed acceptable precision, and there was good agreement for the in vitro sample of slag from Pile D and the sample from Pile D previously used in the Swine Study.

11.13.3 Calculated Bioavailability of Lead in Soils

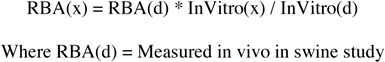

Bioavailability using the in vitro bioaccessibility results was estimated using the Bioaccessibility Ratio Method, as follows:

Results for lead are shown in Table 11-14.

Table 11‑14. Estimation of RBAs for Lead using Bioaccessibility Ratio Method

| Pile | In Vitro | RBA |

|---|---|---|

| D | 12 | 0.17 |

| A | 73 | 1.00* |

| B | 78 | 1.00* |

| C | 42 | 0.60 |

| E | 66 | 0.94 |

| F | 47 | 0.67 |

| *Calculated value >1; value of 1.00 assumed | ||

11.13.4 Application of Bioavailability to Risk Assessment

Two alternative values were assumed for RBA for lead: (1) the default of 60% and (2) a value estimated using the results of the in vitro tests to adjust lead absorption estimates for slag piles using the measured (in vivo) value for Pile D as a benchmark. PRGs were calculated between 219 ppm for the construction worker scenario at Piles A and B, and 7,281 ppm for the NCI worker scenario. The PRGs calculated based on the default RBA ranged from 365 ppm for the construction worker scenario to 2,063 ppm for the NCI worker scenario. The concentrations of lead in the on-site slag piles were mostly between 4,000 ppm and 9,000 ppm. Based on these concentrations, it was determined that all of the slag piles may present a potential hazard to workers (especially the CI-worker and the construction worker). Considering the uncertainty and the probable conservatism in the calculations, hazards to the NCI-worker might be within an acceptable range, but there were insufficient data to support this conclusion with confidence.

11.13.5 How Did Bioavailability Results Affect Site Decisions?

The in vitro RBA values were all equal to or greater than the default RBA of 60%. PRGs calculated for Piles C and D based on in vitro RBAs were higher than those calculated using the default RBA (only slightly higher for Pile C). The remaining PRGs based on in vitro RBAs were all lower than the PRGs calculated based on the default RBA, as shown in Table 11-15.

Table 11‑15. Range of PRGs for Lead in Slag

| Slag Pile | NCI Worker | CI Worker | Construction Worker | |||

|---|---|---|---|---|---|---|

| Default RBA | In Vitro RBA | Default RBA | In Vitro RBA | Default RBA | In Vitro RBA | |

| D | 2063 | 7281 | 430 | 1518 | 365 | 1289 |

| A | 2063 | 1238 | 430 | 258 | 365 | 219 |

| B | 2063 | 1238 | 430 | 258 | 365 | 219 |

| C | 2063 | 2080 | 430 | 434 | 365 | 368 |

| E | 2063 | 1324 | 430 | 276 | 365 | 234 |

| F | 2063 | 1859 | 430 | 388 | 365 | 329 |

Using in vitro RBAs in calculating PRGs at this site allowed for a broader range of remediation goals which, given the conservative nature of the calculations, were likely to be protective of human health. However, due to the large variation in bioavailability estimates, PRG calculations ultimately used the USEPA default bioavailability value of 60% for lead.

11.13.6 Regulatory Considerations

In response to the request to release the slag piles for beneficial land use, USEPA and the state used the new PRG calculations for the site and ultimately decided to use the USEPA default bioavailability value of 60% for lead. Because the community requested future land use be considered in the remedy selection, slag piles were not moved outside the OU2 and graded to better support redevelopment and appropriate soil covers were designed as an interim measure to facilitate future redevelopment. Land use controls were also selected for OU2 to restrict future excavations and guide future use of the property (see (USEPA n.d.; 2002b; 2014b). Redevelopment began once the institutional controls were established and the Ready for Re-use Determination was issued on May 23, 2008. Approximately 65% of the site has been fully developed for mixed use that incorporates major retail and office space, along with needed housing for Midvale City.